Centrifuge for Lab Automation

”Robo-Ready” Series for Lab Automation

Step Stop Centrifuges

In the future, lab automation is expected to increase.

Lab automation is expected to increase operational efficiency, reliability of results, and reproducibility.

However, the combination of lab automation and centrifuges is not a good relationship.

Although centrifuges are general-purpose laboratory instruments, they cannot stop the rotor at a defined position.

Step stop mixer-centrifuge stop the rotor at defined positions so that the robot arm can pick up the sample tubes.

TOMY-RESO will support the lab automation with Step Stop Centrifuges.

Robo-Ready is a series of centrifuges with a rotor stops at a defined position developed for lab automation.

This centrifuge is for lab automation.

Made In Japan

System Integrator

Friendly

Step Stop Mixer-CentrifugeSMCR-M004

Features

Step stop mixer-centrifuge stop the rotor at defined positions so that the robot arm can pick up the sample tubes.

to assist the robot in handling sample tubes.

Spin-Down* and Mixing in a Single Unit

・SMCR-M004 can quickly spin-down 1.5 ml / 2.0 ml × 4 microtubes**.

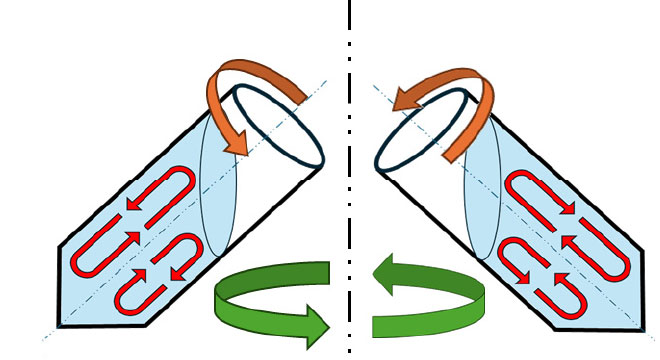

・In the mixer function, the sample tube is self-rotation and the rotor with sample tube orbits around its centrifugal axis, allowing the sample to be mixed very efficiently while minimizing foaming. In particular, liquid sample mixing is highly effective.

*Spin-down is the collection of the sample from the lid and sides of the tube sample to the bottom by centrifugation for a few seconds.

**Working with robot (2.0 ml × 8 microtubes available if not used with robot)

SMCR-M004 with a letter-sized footprint - 8.5 × 11 in

・For efficient use and saving space of laboratory.

・The communication is a contact input that does not require a communication program. This makes it easy to integrate into lab automation.

Saving Time and Reducing Error in Robot Handling!

The spin-down and mixing functions are performed by a single unit, and there is no tube transfer from centrifuge to mixer. That saves transfer time of sample tube and avoids errors in robot handling such as not being able to grab the tube.

(Example)

15 sec. / one tube × in case of 4 tubes = 60 sec.

60 sec. reduction!

Planetary Centrifugal Mixing

Step Stop Mixer-Centrifuge, SMCR-M004 equipped with centrifugal function for quick spin-down and mixing function by tube self-rotation. Self-rotating tubes generate up-and-down convection and vortex flow in the sample. These features enable the mixing with less foaming.

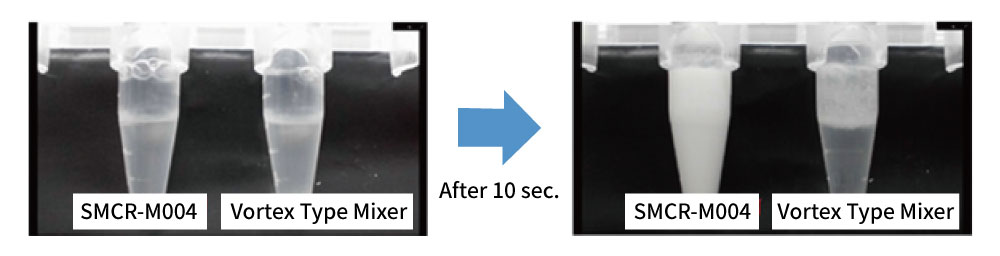

Emulsion Formation

Emulsion formation was performed using 0.1M sodium dodecyl sulfate (SDS) solution as the aqueous phase and 1-dodecanol added to liquid paraffin as the oil phase. With the vortex mixer, the interfacial tension between the aqueous and oil phases prevented sufficient stirring between the phases, and no emulsion was formed, whereas with the Step Stop Mixer-Centrifuge an emulsion was formed.

Providing documents: FUJIFILM Wako Pure Chemical Corporation

Specification

| Product | Step Stop Mixer-Centrifuge |

|---|---|

| Model | SMCR-M004 |

| Rotor Stopping potions | 8 positions (Rotate Angle every 45°) |

| Speed | 4,000 rpm (Centrifuge Mode, Fixed) 2,500 rpm (Mixer Mode, Fixed) |

| RCF | 1,170 G (Centrifuge Mode) |

| Max. Capacity | 2.0 ml× 8 microtubes 2.0 ml× 4 microtubes (Working with Robot) |

| Timer | 6 minutes (Fixed) |

| Dimension | 214W × 270D × 138H (Lid Open 231H) mm |

| Net Weight | Approx 2.5 kg |

| Power Requirements | Dedicated AC adapter Input : 1-Phase AC100-240 V 50 / 60 Hz 1.8 A |

| External Interface | Input Rotor rotate (Contact Signal) Centrifuge Start / Stop (Contact Signal) Mixer Start / Stop (Contact Signal) Output Error (Transistor / Sink Output) |

| Safety Devices | Lid Opening Interlocking Brake Overload Protector(AC adapter, Motor Driver) |